##Executive Summary

Emergency dispatch is the moment your daily plan stops working. A technician overruns a job, a priority customer calls, a safety issue appears on-site, or a missing part forces a reassignment. These disruptions aren’t exceptions — they are part of real field operations.

This guide explains how to design an emergency-ready workflow on top of your existing FSM platform. You’ll learn how emergency dispatch works end-to-end, which capabilities matter most, what off-the-shelf systems provide, and when hybrid or custom modules create the most ROI.

What Is Emergency Dispatch Software?

Emergency dispatch software helps field-service teams respond quickly and accurately when an unexpected event disrupts the schedule. Where routine scheduling assumes stable conditions, emergency dispatch is designed for uncertainty — shifting job durations, last-minute client requests, missing parts, or technician unavailability.

Definition and Core Purpose

Emergency dispatch software provides a real-time decision layer on top of your FSM. It helps dispatchers:

- Identify the right technician for an unexpected job

- Verify parts availability in vans and warehouses

- Adjust the schedule without causing ripple effects

- Route technicians based on real-time conditions

- Keep customers updated with accurate ETAs

Its purpose is not just speed — it is clarity under pressure, ensuring the right technician arrives prepared, with the right parts, within SLA timeframes.

Routine vs Emergency Scheduling

Routine scheduling assumes predictable workflows:

- Standard job durations

- Known technician availability

- Predefined appointment types

- Stable inventory

Emergency dispatch assumes the opposite. Jobs run long, priorities shift, or a technician becomes unavailable. A day planned at 7 AM may look entirely different by noon.

Emergency workflows include situations like:

- A certified tech is required

- A job overruns and disrupts the afternoon schedule

- A high-priority client requests immediate support

- A part mismatch is discovered on site

- Weather or traffic alters travel time

These events require rapid reprioritization based on real data — skills, parts, SLAs, routing, and technician status.

Why Standard FSM Tools Struggle

Most FSM platforms are built around predictable flows and broad job categories. Their limitations in emergencies often include:

- Rigid workflows that don’t support mid-day reshuffling

- Skill categories that are too general

- Limited visibility into van-level inventory

- SLA handling that doesn’t surface priority contracts reliably

- Weak insight into downstream schedule impact

- Slow or manual routing adjustments

This is why many companies add a custom emergency layer: their internal rules for skills, priorities, safety, and parts are more complex than off-the-shelf logic allows.

The Business Impact of Emergency Dispatch

Emergency dispatch affects revenue, service quality, technician productivity, and contract performance. When teams handle disruptions well, operations stay stable. When they don’t, delays multiply, SLA penalties increase, and customers lose trust.

Operational Risk Exposure

Unplanned events expose gaps in process and systems. Common risks include:

Technician Mismatch Assigning someone without the right skill, certification, or equipment leads to delays and repeat visits.

Inventory Uncertainty Without accurate van-level stock visibility, dispatchers rely on guesswork — often resulting in unprepared technicians.

SLA Violations Priority customers expect rapid response. Missing contract windows creates penalties and relationship risk.

Schedule Cascade Effects One emergency can push the entire day behind unless the system shows how each change affects other jobs.

Dispatcher Overload When information is scattered across tools, dispatchers lose time collecting context instead of coordinating the response.

ROI Drivers in Emergency Dispatch

Improvements in emergency handling typically result in:

Higher First-Time Fix Rates Skill-based matching + accurate parts visibility reduce repeat visits — the most expensive failure mode.

Fewer Wrong-Tech/Wrong-Parts Dispatches Every failed dispatch wastes labor, fuel, opportunity cost, and technician morale.

Faster Response Time With real-time data, decisions take minutes instead of back-and-forth calls.

Better Technician Utilization Technicians spend more time on jobs and less time waiting, rerouting, or returning for parts.

SLA Protection Meeting response-time obligations supports renewals for high-value customers.

Hidden Costs of Mis-Dispatching

Not all losses show up immediately, but they accumulate:

Direct Costs

- Repeat truck rolls

- Unnecessary overtime

- Long travel caused by incorrect routing

- Idling technicians

Typical cost range: $300–$500 per failed dispatch, excluding lost customer confidence.

Indirect Costs

- Delayed response to other clients

- Dispatcher burnout

- Technician frustration

- Contract churn

- Lower customer satisfaction

For many field businesses, the ability to handle disruptions efficiently becomes a real competitive differentiator.

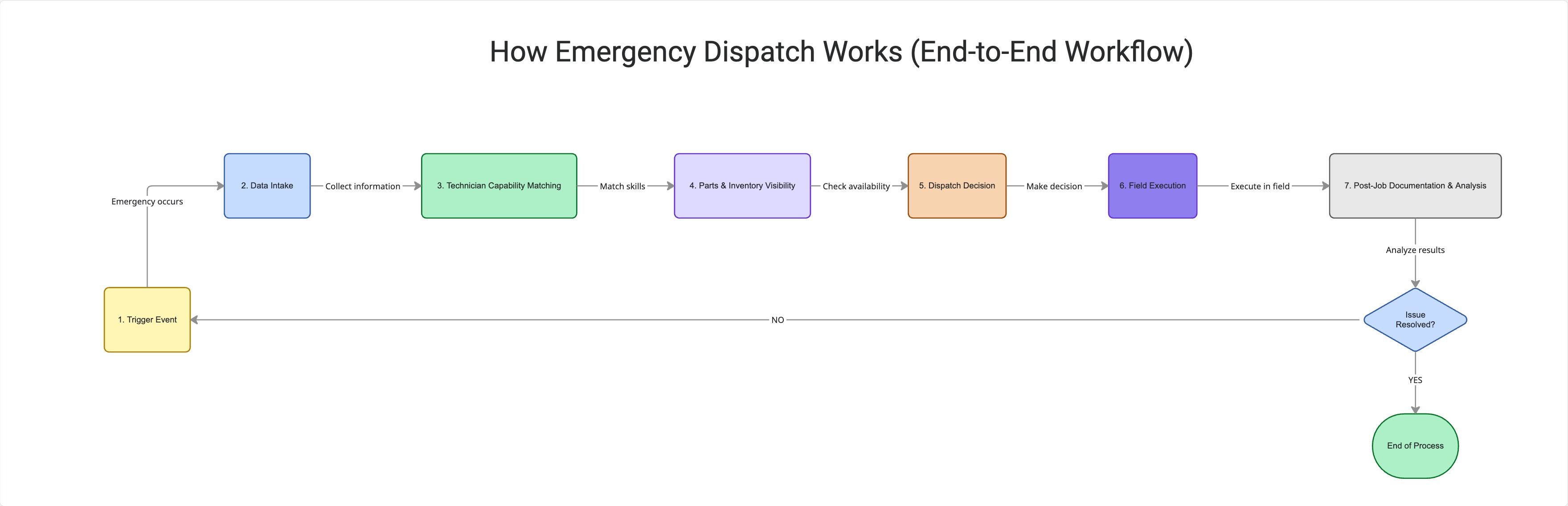

How Emergency Dispatch Works (End-to-End Workflow)

Emergency dispatch appears chaotic from the outside, but it follows a consistent pattern. A strong system supports each step — from the moment a disruption occurs to the final post-job documentation.

Trigger Events: When the Plan Breaks

Emergency workflows begin when something diverges from the plan:

- A job takes longer than expected

- A client requests immediate support

- A technician becomes unavailable

- A safety concern is escalated

- A critical part is missing

- A multi-step job reveals additional work

- Weather or access restrictions disrupt routing

These moments require dispatchers to pause and reconsider the schedule quickly. Software helps surface necessary information without losing time.

Data Intake: Collecting What Matters

As soon as the trigger occurs, the system should consolidate:

- Job details + customer information

- SLA tier and response-time rules

- Equipment type and history

- Technician load and availability

- Real-time location and traffic

- Certification or compliance requirements

- Photos, notes, or previous issues

This is where many teams struggle when using multiple disconnected tools. A dedicated module brings everything into one place.

Technician Capability Matching

Once context is clear, the next question is: Who can handle this job right now?

Matching requires more than checking availability. It includes:

- Certifications/licensing

- Experience with specific equipment or job type

- Safety or regulatory constraints

- Proximity and travel time

- Current job progress

- Two-person requirements

- Shift considerations or break windows

Every service company has its own logic for capability matching. Off-the-shelf FSM platforms rarely capture these nuances, which is why custom capability engines are often added.

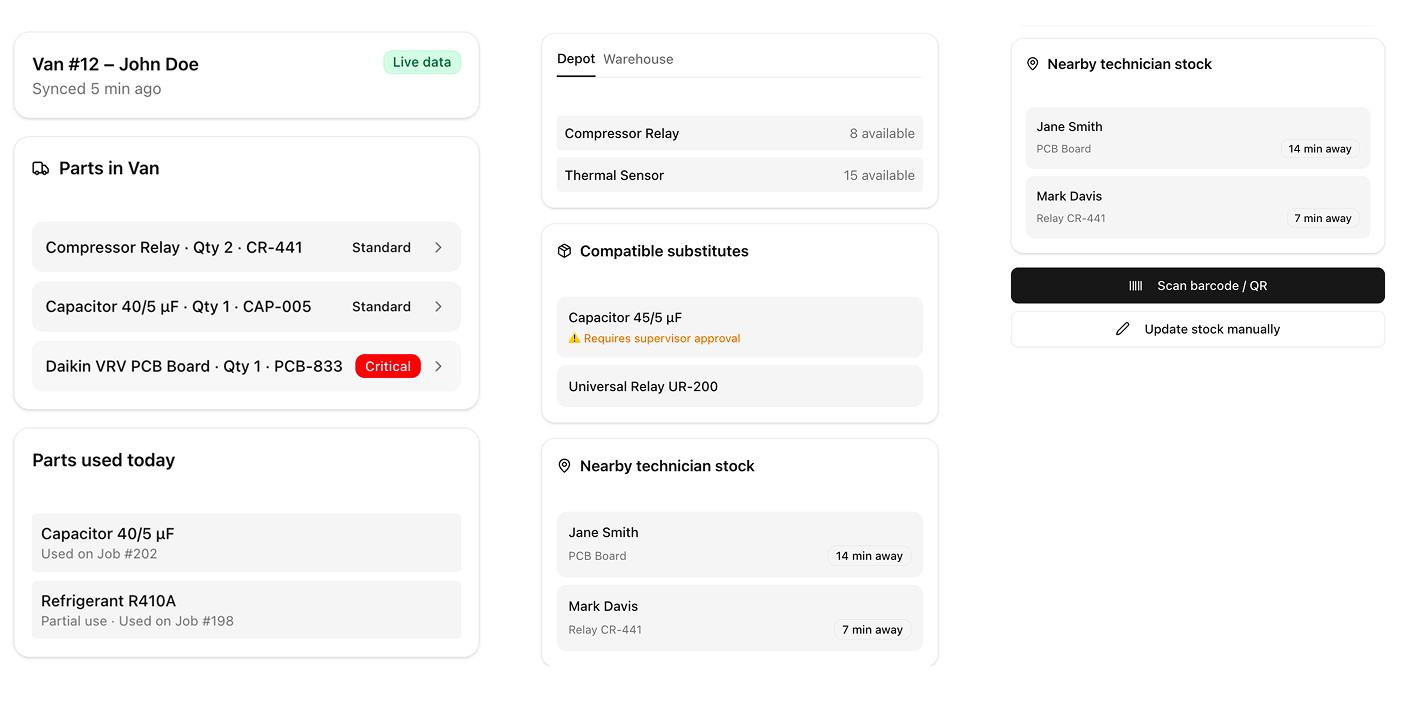

Parts and Inventory Visibility

Skill matching is only half the decision. Technicians must also arrive with the correct parts.

A strong system checks:

- Real-time van stock

- Recent part usage

- Warehouse/depot availability

- Substitute parts

- Transfer options between nearby technicians

Without this visibility, dispatchers make assumptions — and technicians arrive unprepared. Many teams implement custom integrations to track van-level stock accurately.

The Dispatch Decision: Rebuilding the Plan

Once data is available, dispatchers must determine:

- Who goes

- With which parts

- What job gets delayed

- How the change affects other appointments

- What communication is required

- What the updated ETA is

A good system shows ripple effects clearly and rebuilds the plan around constraints: skills, SLAs, parts, routing, and technician workload.

Field Execution and Feedback Loop

After dispatch:

- Technicians receive updated job details

- Routing adapts to traffic

- Safety instructions or job notes appear

- Progress updates flow back to dispatch

- New issues can be escalated in real time

This two-way communication keeps everyone aligned as conditions continue to change.

Post-Job Documentation and Analysis

The system should capture:

- Actual time on site

- Parts consumed

- Photos and notes

- Follow-up requirements

- SLA compliance

- Impact on subsequent jobs

This data becomes valuable for improving future emergency logic.

Example Scenario

A data center reports abnormal behavior in a rooftop cooling unit at 2 AM. It’s not a failure yet, but waiting risks downtime.

The dispatcher must instantly know:

- Which technicians are certified on that specific VRF model

- Who has the correct replacement components

- Which clients hold priority contracts

- How diverting someone affects early-morning appointments

The company uses a standard FSM for routine scheduling, but relies on a custom emergency dispatch board that surfaces real-time certifications, SLA rules, and van inventory.

It identifies the only technician with both the certification and the required part. It also highlights which planned jobs can be safely delayed.

This hybrid setup prevents mis-dispatching — previously costing ~$400 per incident — and quickly demonstrates measurable ROI.

Core Features Every Emergency Dispatch System Needs

Emergency dispatch is not about reacting faster — it is about making the right decision without losing stability in the rest of the schedule. Dispatchers need immediate clarity: who is qualified, what parts are available, what can be shifted safely, and which clients require priority attention.

The features below form the foundation of an emergency-ready system.

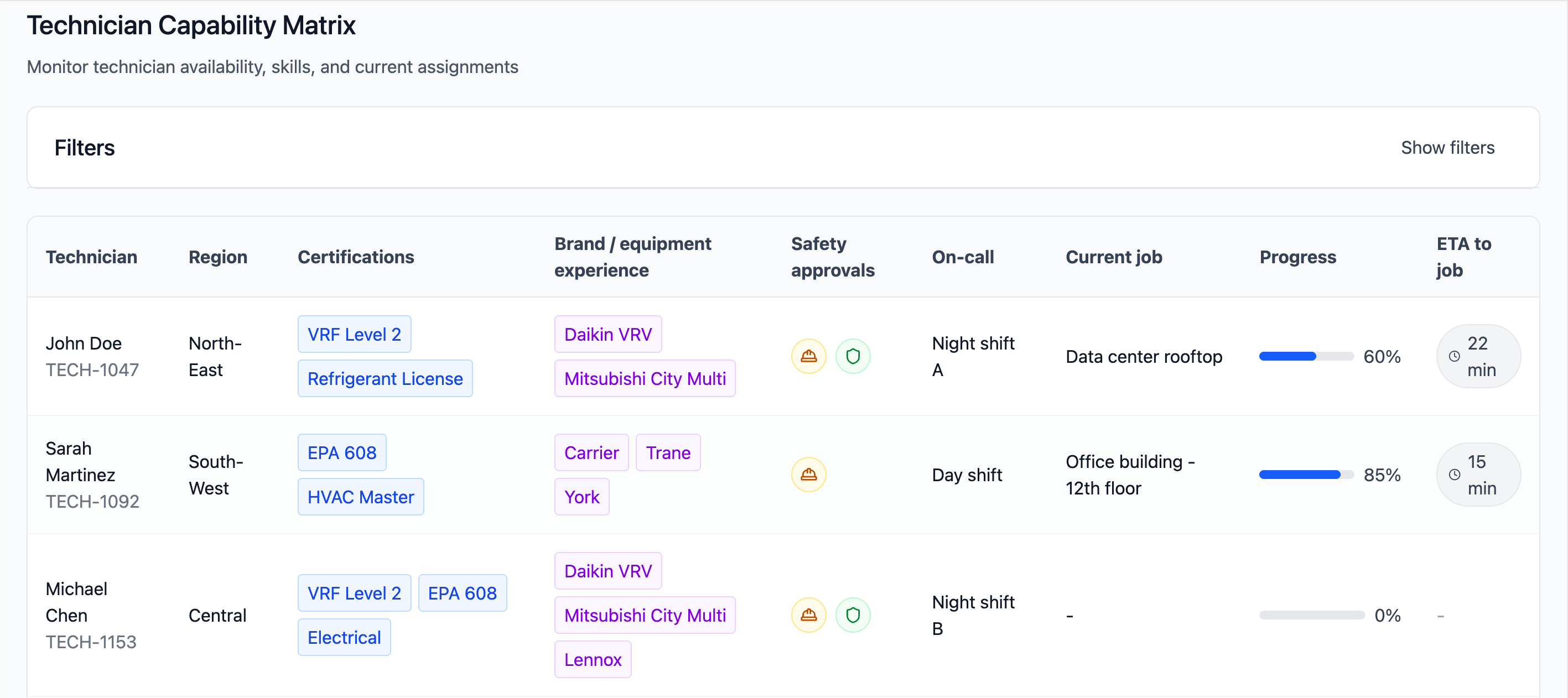

Technician Skills, Certifications & Capability Matrix

When the schedule breaks, the first question is: Who is actually qualified to take this job?

An effective capability matrix includes:

- Certification levels

- Brand- or equipment-specific experience

- Safety or regulatory requirements

- Real-time job progress

- On-call rotations

- 2-person job requirements

- Technician proximity and travel time

This only works if technician data is accurate. For companies onboarding contractors, automated onboarding creates consistency: structured profiles, certifications, licensing dates, and integration with HR/LMS systems.

Why it matters: Misassigning a technician quickly becomes the costliest error in emergency dispatch — lower FTFR, second truck rolls, unhappy clients, and SLA violations.

How companies implement it:

- FSM fields (if flexible enough)

- A custom capability microservice

- Automated sync from onboarding → certification matrix

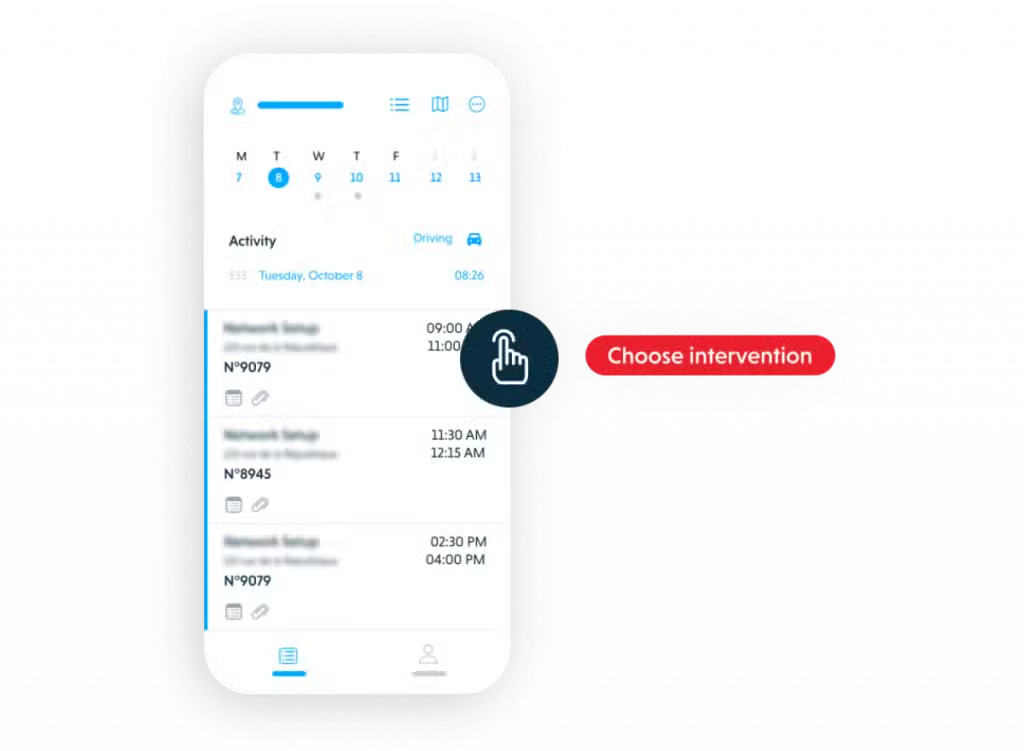

In the software, the technician capability matrix doesn’t have to be a spreadsheet. It usually appears as a filtered grid: each technician row shows certification tags, brand experience, safety approvals, current job progress, on-call status, and estimated travel time to the new job. When an emergency comes in, the system ranks technicians based on this matrix instead of just showing “who is free”.

Real-Time Inventory & Van Stock Visibility

Even the most skilled technician cannot complete an emergency job without the right part. This is where many FSM systems fail — they track inventory broadly but not van-level stock.

A robust emergency-dispatch setup provides visibility into:

- Parts in each van

- Parts used earlier in the day

- Depot and warehouse stock

- Substitute parts

- Transfer options between technicians

- Multi-region availability

Why it matters: “Wrong-parts dispatches” are among the most expensive incidents in field operations. Preventing them drives FTFR and reduces rescheduling, travel time, and customer frustration.

How companies implement it:

- FSM inventory module + real-time integrations

- ERP or WMS sync

- Mobile app workflows with barcode/QR updates

This is often a hybrid setup: FSM handles global inventory, while a custom logic layer manages real-time van stock.

SLA & Priority Logic Engine

Not all emergencies are equal. Some are contractual obligations.

A strong dispatch engine must understand:

- SLA levels

- Required response times

- Multi-site contract rules

- Penalty windows

- Escalation workflows

- VIP client categories

Why it matters: SLA violations damage high-value relationships and create financial penalties. The system must surface priority jobs automatically and warn dispatchers when windows shrink.

Implementation:

- FSM rules engine (if adaptable)

- Custom SLA service pulling from CRM

- Many companies customize this area heavily because SLA structures vary widely.

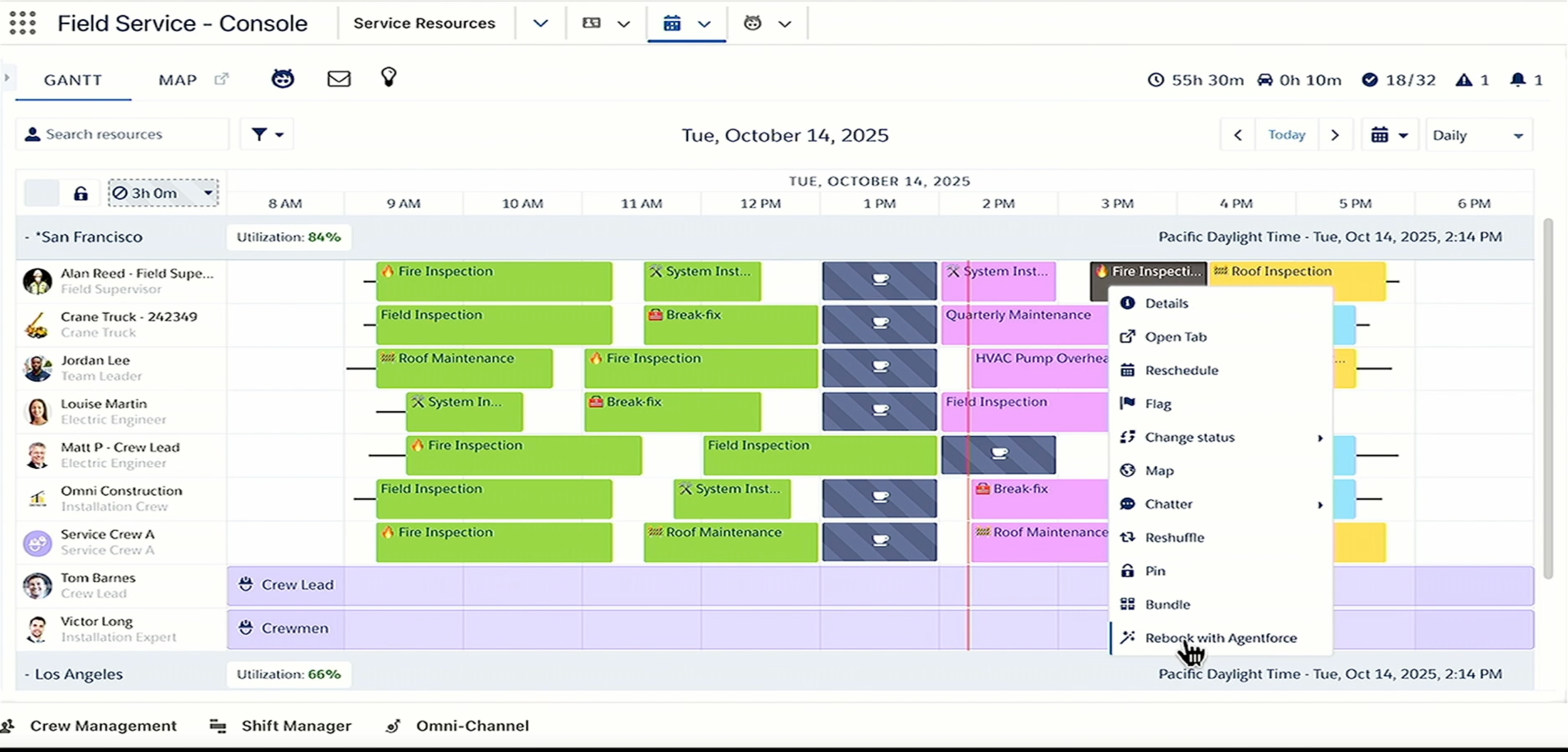

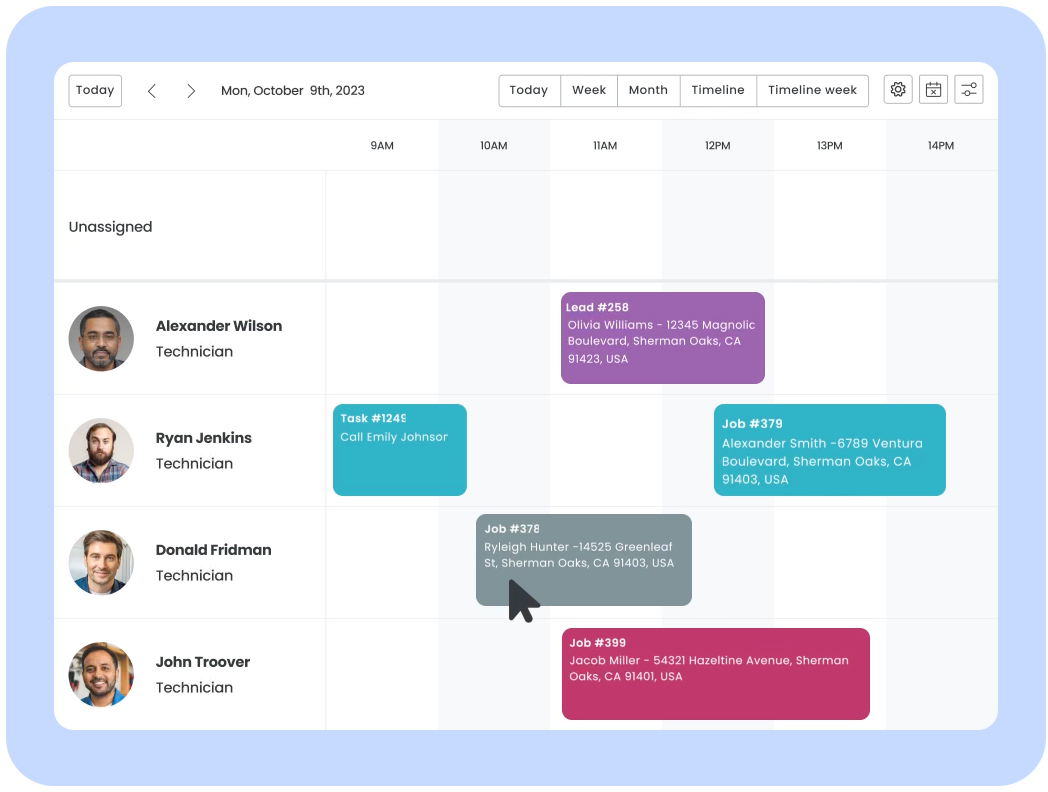

Live Schedule Disruption Handling

This capability is the “core” of emergency dispatch: adjusting the schedule quickly and accurately without collapsing the rest of the day.

A strong disruption-management engine supports:

- Drag-and-drop reassignment

- Real-time availability updates

- Ripple-effect visualization

- Safe rescheduling recommendations

- Job splitting or pausing

- Multi-location coordination

Why it matters: One urgent job can disrupt five others if the system does not clearly show how changes affect the day. Dispatchers need a single place where they can recalculate the plan in minutes.

Common implementation: A custom dispatch board layered on top of the FSM system.

Routing & Travel Optimization

Travel efficiency is crucial under emergency conditions.

Routing must consider:

- Technician proximity

- Traffic conditions

- Road restrictions

- Weather

- Multi-job route chains

- Vehicle-specific constraints

Why it matters: Minutes saved can determine SLA success or failure.

Implementation:

- FSM routing (for routine work)

- Third-party routing APIs

- Custom routing microservice for complex constraints

A hybrid model is common: FSM handles standard routing, while custom logic supports emergency cases.

Unified Two-Way Communication

Emergencies introduce rapid changes — every stakeholder must stay aligned.

A complete solution includes:

- Instant push notifications

- Real-time technician updates

- In-app chat or messaging

- Photo/video reporting

- Safety alerts

- Route adjustments

- Arrival/complete confirmations

Why it matters: Communication failures are one of the fastest ways for emergency workflows to unravel.

Emergency Analytics & Continuous Improvement

Emergency dispatch becomes more accurate as teams learn from past disruptions.

Analytics should track:

- Mean time to dispatch

- First-time fix rate

- SLA compliance

- Technician capability patterns

- Parts availability issues

- Travel inefficiencies

- Dispatcher manual overrides

- Cost of misdispatches

Why it matters: Patterns in emergency requests reveal training gaps, staffing needs, stocking rules, and process improvements.

Off-the-Shelf Emergency Dispatch Options

Most field-service companies begin with an off-the-shelf FSM platform. These systems support routine scheduling and some degree of dispatching, but they vary widely in how they handle real-time disruptions.

Below is a realistic view of what they do well and where teams often hit limits.

What Off-the-Shelf FSM Tools Provide

Most commercial FSM platforms include:

- Calendar scheduling

- Basic routing and travel optimization

- GPS tracking

- Job foms and checklists

- Inventory tracking

- CRM + invoicing

- Customer notifications

- Reporting dashboards

They work well for planned maintenance, installations, and standard service calls.

Strengths of Off-the-Shelf Systems

- Quick implementation

- Lower upfront cost

- Familiar workflows for common trades

- All-in-one functionality

- Good for predictable operations

For many companies, these tools handle 60–70% of daily scheduling needs effectively.

Real Examples of Off-the-Shelf Solutions

Salesforce Field Service

Enterprise FSM built on Salesforce. Strengths: advanced routing, customization, real-time coordination. Limitations: capability logic and van inventory often require custom objects or integrations.

Praxedo

Cloud FSM with strong real-time scheduling. Strengths: efficient dispatching, solid mobile app. Limitations: multi-tier SLA logic and vehicle-specific stock depth.

Workiz

Ideal for small/mid-size HVAC, plumbing, appliance teams. Strengths: easy-to-use, fast dispatching. Limitations: limited advanced certification matching and inventory depth.

FieldPulse

Scheduling-driven FSM with intuitive UI. Strengths: flexible job reprioritization, real-time GPS. Limitations: lacks advanced SLA rules and deep capability logic.

Where Off-the-Shelf Tools Struggle

Off-the-shelf FSM platforms often fall short in:

- Multi-constraint technician matching

- Van-level inventory accuracy

- Complex SLA structures

- Real-time disruption modeling

- Deep routing constraints

- Unified data visibility across systems

- Multi-region operations

These gaps become more obvious as the business scales or handles more high-priority clients.

Why Many Teams Adopt Hybrid or Custom Solutions

Once operations involve:

- Priority contracts

- Complex equipment

- Multi-trade teams

- Frequent mid-day changes

- Multi-region inventory

- Strict SLA windows

A generic FSM cannot represent the company’s real dispatch logic.

This leads teams to:

- Keep the FSM for routine scheduling

- Add a custom emergency dispatch board

- Integrate capability logic, SLA rules, inventory, routing

- This hybrid structure is the most common end-state for mature service businesses.

When You Need Custom or Hybrid Solutions

Emergency dispatch is built on exceptions, not routines. When the way your team handles disruptions becomes a competitive advantage — or a bottleneck — it’s time to consider extending your FSM with custom logic.

Operational Indicators You’ve Outgrown FSM Tools

You may need a custom or hybrid setup when:

- Recurring “edge cases” don’t fit the system

What the FSM sees as edge cases may be daily reality — multi-equipment jobs, safety constraints, varied job durations.

- Frequent mid-day technician reassignments

If dispatchers consistently override the FSM, the system isn’t supporting real operations.

- Inventory uncertainty at the van level

Most off-the-shelf systems track warehouse-level stock, not per-van availability.

- SLA complexity the FSM cannot model

Tiered contracts, multi-site rules, and penalty windows require deeper logic.

- Dispatchers rely on external spreadsheets or notes

This indicates the system cannot encode your operational rules.

- Your internal rules cannot be modeled in the FSM

Companies often have unique logic around task assignment, priority handling, and stocking patterns.

Example Scenario: Why Hybrid Logic Wins

A data center reports abnormal behavior in a rooftop cooling unit at 2 AM. The dispatcher must identify the only technician certified on that VRF model, confirm they have the correct replacement component, and understand how diverting them impacts the early-morning schedule.

A custom emergency board pulls:

- Certification data

- Van inventory

- SLA tiers

- Technician availability

The system identifies the technician who can complete the job on the first visit and highlights which scheduled jobs can shift safely.

This eliminates misdispatches previously costing ~$400 each. The hybrid system pays for itself within weeks.

Why Hybrid Solutions Make Sense

Hybrid solutions balance stability with flexibility:

Your FSM handles:

- Planned maintenance

- CRM

- Invoicing

- Timesheets

- Basic routing

Your custom layer handles:

- Real-time skill and certification logic

- Van-level inventory accuracy

- SLA rules

- Dispatch board

- Complex routing

- Regional variations

This gives companies precise control during unplanned events without rebuilding everything.

What Companies Typically Customize

The most common custom modules include:

Custom dispatch board — a real-time operational cockpit Capability engine — technician skills, certifications, constraints SLA logic module — reflects unique contract conditions Inventory engine — real-time van and warehouse stock Automated communication flows — faster response Routing logic — complex constraints, multi-region Data consolidation layer — unified data across systems

These components directly reduce misdispatches and improve reliability.

Architecture Options for Implementing Emergency Dispatch

Companies take different architectural paths depending on complexity, systems, and maturity.

Extending an Existing FSM Platform

Works when:

- Emergencies are simple

- Technicians share similar skills

- Inventory is manageable

- SLAs are straightforward

Pros: low cost, no new UI Cons: limited flexibility, difficult to maintain as complexity grows Best for: early-stage or small teams

Building a Separate Emergency Dispatch Application

Here, the FSM stays as the system of record, but a dedicated application handles real-time decisions.

Pros:

- Encodes unique logic

- Accurate capability matching

- Real-time inventory & SLA visibility

- Faster under pressure

Cons:

- Requires upfront investment

- Needs integration work

Best for: companies with frequent disruptions or strategic emergency workflows.

Hybrid / Microservices Architecture

The most flexible and scalable approach. Emergency logic is broken into microservices:

- Capability engine

- SLA engine

- Inventory engine

- Routing engine

- Notification service

- Real-time orchestration

These feed a custom dispatch UI.

Pros:

Modular, easy to evolve Works across multiple systems Ideal for multi-region, multi-business-unit companies

Cons: requires technical maturity

Integration Considerations

Emergency dispatch relies on clean, timely data from:

- FSM (jobs, schedules, availability)

- CRM (contracts, SLAs)

- Inventory/WMS (parts)

- HR/Onboarding (certifications)

- GPS/Telematics

- Knowledge base

- IoT systems

Critical requirements:

- Real-time sync

- High data accuracy

- Clear source-of-truth ownership

- Minimal latency

Choosing the Right Approach (Decision Framework)

Selecting the right emergency-dispatch architecture depends on how your operations function when disruptions occur. This framework helps determine whether you should extend your FSM, add a custom dispatch layer, or adopt a hybrid or microservices model. For a deeper dive into this strategic choice, read our guide on build vs. buy field service management software.

Step 1 — Map Your Current Dispatch Reality

Document how your team handles disruptions:

- Frequency of technician reassignment during the day

- Number of emergency or priority calls

- Clients with strict SLA rules

- Technician skill and certification differences

- Accuracy of van-level inventory

- Use of spreadsheets or manual notes

- Wrong-tech or wrong-parts incidents

- Average time-to-dispatch under pressure

This exposes where your current workflow breaks.

Step 2 — Identify What Must Improve Immediately

Teams typically focus on:

- Reducing misdispatches

- Increasing first-time fix rates

- Protecting SLA response windows

- Reducing dispatcher workload

- Avoiding schedule collapse

- Improving real-time inventory accuracy

- Shortening decision cycles

These priorities guide the approach.

Step 3 — Compare Architecture Options

Option A — Extend your FSM

Suitable when emergency workflows are simple and technician capabilities are similar.

Option B — Add a custom emergency-dispatch layer

Works when routine scheduling fits the FSM but emergencies require deeper logic.

Option C — Hybrid or microservices architecture

Ideal for multi-region operations, varied service lines, and long-term scalability.

Step 4 — Define Budget, Timeline, and Team Constraints

- Low budget → extend FSM

- Medium budget → custom emergency module

- High budget → hybrid or microservices

- Need fast rollout → FSM extension

- Strategic investment → modular architecture

- Limited IT capacity → minimal change

- Strong engineering capability → microservices

Step 5 — Align With Business Strategy

- Desire for stability → extend FSM

- Need for precision → custom emergency module

- Regional expansion → hybrid architecture

- Long-term tooling → microservices

The 60–30–10 Rule

- 60% of work fits standard FSM workflows

- 30% needs enhanced logic

- 10% requires real-time emergency handling

If the top 10% causes most friction, a dedicated emergency module is needed.

Integrations: Data Sources That Make Emergency Dispatch Accurate

Emergency-dispatch quality depends on real-time, reliable data. No single system holds everything needed for accurate decision-making, so integrations become essential.

FSM System — Jobs, Schedules, Availability

FSM provides:

- Planned jobs

- Technician calendars

- Job durations

- Field updates

- Appointment windows

Emergency logic relies on this for resource and schedule alignment.

CRM and Contract Data — SLA and Priority Rules

CRM systems store:

- SLA tiers and response-time guarantees

- Penalty windows

- Warranty rules

- Priority client tiers

- Multi-site contract structures

This determines priority handling.

Inventory, Warehouse, and Van Stock

Accurate emergency dispatch relies on:

- Van-level inventory

- Depot and warehouse stock

- Substitute parts

- Recently consumed components

- Transfer options

This prevents technicians arriving unprepared.

HR, Onboarding, and Certification Data

Technician matching requires:

- Certifications and licensing

- Equipment-specific training

- Safety clearances

- Expiration dates

- Regional restrictions

This ensures compliance and safety.

Telematics, GPS, and Fleet Data

GPS provides:

- Technician location

- Arrival estimates

- Route progress

- Traffic conditions

Proximity must reflect real movement.

Knowledge Base and Equipment History

Emergency jobs benefit from:

- Troubleshooting guides

- Diagrams and schematics

- Parts lists

- Past job notes

- Safety steps

Technicians gain context instantly.

IoT and Real-Time Equipment Alerts

Connected devices generate:

- Fault codes

- Sensor alerts

- Predictive warnings

- Operating anomalies

Some emergencies are triggered before the client calls.

Communication Systems

Effective emergency workflows require:

- SMS and push notifications

- Email alerts

- In-app messaging

- Arrival updates

- Technician status changes

Two-way communication keeps everyone aligned.

Data Flow and Latency Requirements

Emergency-dispatch systems need:

- Near real-time sync

- Clear source-of-truth ownership

- Minimal latency

- Consistent data across systems

Decisions must use accurate, current information.

Implementing Emergency Dispatch (Step-by-Step Roadmap)

Emergency-dispatch capabilities can be added gradually. Each phase reduces operational friction and increases stability.

Phase 1 — Evaluate Current Workflow

Map how emergencies are handled:

- Entry points for emergency requests

- Where delays occur

- How dispatchers gather context

- Root causes of misdispatch

- Time-to-dispatch

- Common workflow failures

Phase 2 — Define Your Emergency Decision Logic

Document rules typically held in dispatchers’ heads:

- SLA prioritization

- Certification requirements

- Safety constraints

- Inventory needs

- Routing constraints

- Regional differences

This creates a usable decision tree.

Phase 3 — Choose the Architecture

Select the model based on operational complexity:

- Extend FSM

- Build custom emergency module

- Hybrid or microservices

Phase 4 — Integrate Core Data Sources

Integrate:

- Technician availability

- Certifications

- Van-level inventory

- SLA contract details

- GPS

- Job progress

This enables a unified decision layer.

Phase 5 — Build or Configure the Dispatch Board

The dispatch board should show:

- Technician skills and certifications

- Real-time locations

- Job status

- Inventory availability

- SLA levels

- Ripple-effect visibility

- Recommended technician matches

- Routing suggestions

Phase 6 — Add Automation and Communication

Automate:

- Technician alerts

- Customer updates

- SLA warnings

- Inventory validation

- Reassignment logic

Reduces manual steps during emergencies.

Phase 7 — Pilot in a Controlled Environment

Start with:

- One region

- One job type

- One high-priority client segment

Validate:

- Technician matches

- Inventory accuracy

- SLA performance

- Dispatcher workload

- Customer feedback

Phase 8 — Add Analytics and Continuous Improvement

Track:

- Mean time to dispatch

- First-time fix rates

- SLA compliance

- Inventory shortages

- Manual overrides

- Cost of disruptions

Data guides refinement.

Phase 9 — Optional: Productize Internal Tools

If internal tools provide significant value:

- Make components reusable

- Connect to multiple FSM systems

- Provide portals for partners

- Explore monetization

Emergency-dispatch capability becomes a strategic asset.

Measuring Success: KPIs for Emergency Dispatch

These KPIs reveal whether emergency workflows are getting faster, more accurate, and more stable.

Dispatch Efficiency

- Mean Time to Dispatch (MTTD)

- Mean Time to Acknowledgment (MTTA)

- Actual arrival time vs estimated

First-Time Fix Performance

- FTFR for emergency jobs

- Wrong-tech or wrong-parts incidents

Inventory Accuracy

- Van-level inventory accuracy

- Time lost due to missing parts

SLA Compliance

- SLA response-time success

- Near-miss alerts

- Priority job accuracy

Dispatcher and Technician Performance

- Manual overrides

- Technician utilization

- Travel vs productive time

Customer Experience

- Emergency NPS

- Repeat emergency calls

Operational Stability

- Ripple effect on downstream jobs

- Disruptions contained

- Overtime generated

Financial Indicators

- Cost per emergency dispatch

- Savings from reduced misdispatches

- Retention of high-value clients

Before-and-After Benchmarking

- MTTD

- FTFR

- SLA compliance

- Misdispatch frequency

- Escalation volume

- Cost of disruptions

Emergency Dispatch for Multi-Region Operations

Emergency dispatch becomes more complex when a company operates across multiple regions. Different locations often have different technician capabilities, inventory rules, regulations, and traffic patterns. A single system must reflect these differences without slowing down real-time decision-making.

Regional Variations That Affect Dispatch

Multi-region operations introduce differences in:

- Technician distribution and skill levels

- Licensing and certification requirements

- Average travel times and traffic conditions

- Depot and warehouse availability

- Stocking patterns for parts and equipment

- Local service hours or union rules

- Weather patterns and accessibility

- SLA variations across enterprise clients

These factors must be encoded into the dispatch logic.

Data Separation and Shared Logic

A multi-region architecture must balance shared standards with region-specific workflows.

Shared components:

- Core scheduling data

- SLA logic structure

- Dispatch board interface

- Overall data model

- Compliance frameworks

Region-specific elements:

- Certification matrices

- Inventory rules

- Routing heuristics

- Priority rules for major accounts

- Seasonal or climate constraints

This prevents one region’s rules from distorting another’s schedule.

Inventory and Parts Availability by Region

Each region may have:

- Different van stock requirements

- Unique stocking policies

- Separate depots or micro-warehouses

- Region-specific substitutes or part variations

Emergency dispatch must recognize these variations to avoid misdispatches.

Cross-Region Technician Support

During high demand, regions may borrow technicians from neighboring areas. The system should be able to:

- Calculate travel feasibility

- Check cross-region certifications

- Verify inventory compatibility

- Respect regional SLA constraints

This ensures cross-support decisions are safe and profitable.

Example Scenario: Covering a Surge in a Neighboring Region

A winter storm creates a spike in furnace failures across Region A. Region B has available technicians with the right certifications.

The dispatch system must instantly evaluate:

- Travel time and road restrictions

- Certification validity across regions

- Availability of required replacement parts

- Regional SLA priority

- Impact on Region B’s schedule

This prevents both service gaps and unnecessary ripple effects.

Cost and ROI Planning for Emergency Dispatch Software

Emergency-dispatch capabilities generate measurable value by reducing errors, protecting SLAs, and increasing technician productivity. ROI becomes visible once misdispatches, travel inefficiency, and rework decrease.

Cost Categories to Plan For

Key cost components include:

- Discovery and requirements analysis

- Custom development (if needed)

- Integrations with FSM, CRM, WMS, HR

- Real-time routing and telematics APIs

- Data consolidation or middleware

- Dispatch board UI

- QA and phased rollout

- Training for dispatchers and technicians

- Maintenance and future updates

For many companies, the first step is a discovery phase (4–6 weeks) followed by a modular rollout.

Core ROI Drivers

Companies typically see ROI from:

- Fewer wrong-tech / wrong-parts dispatches

- Higher first-time fix rates

- Lower overtime and emergency labor cost

- Improved SLA performance and reduced penalties

- Faster time-to-dispatch

- Lower dispatcher workload

- Better technician utilization

- More accurate inventory planning

- Higher retention of enterprise clients

These metrics improve simultaneously once emergency workflows stabilize.

Calculating ROI

Common financial indicators:

- Cost per misdispatch avoided

- Cost per hour of reduced overtime

- Reduction in SLA penalty exposure

- Savings from improved routing efficiency

- Reduction in job rescheduling

- Inventory cost tied to accurate stocking

Many companies recoup investment within months once misdispatches and rework drop by even 10–15%.

Example Scenario: Reducing Misdispatches by 20%

A team previously averaged 40 misdispatches per month at ~$350 cost per incident.

A dedicated emergency module reduces this by 20%.

- Baseline cost: 40 × $350 = $14,000/month

- Improvement: 8 incidents avoided

- Monthly savings: $2,800

- Annual savings: $33,600

In many deployments, this is only one of several ROI drivers.

Summary

Emergency dispatch is the critical layer that determines whether a daily plan holds or collapses under real-world pressure. When teams can identify the right technician, verify part availability, adjust schedules, and route efficiently, operational stability improves.

What Effective Emergency Dispatch Achieves

- Faster, more accurate decisions under pressure

- Higher technician productivity

- Better customer experience during urgent events

- Stronger SLA performance

- Fewer manual steps for dispatchers

- Reduced job overruns and rescheduling

- Lower operational and financial risk

Why Architecture Matters

Routine work fits most FSM tools. Emergency workflows do not.

A tailored architecture — FSM extension, custom module, or hybrid system — ensures:

- Correct technician matching

- Accurate van-level inventory

- Real-time routing

- Reliable SLA prioritization

- Multi-region consistency

The Path Forward

Emergency-dispatch capability can be implemented gradually:

- Document real decision logic

- Integrate critical data sources

- Add a dedicated dispatch board

- Automate high-friction tasks

- Expand using analytics

Over time, this becomes a durable advantage — and for some industries, even a revenue opportunity when internal systems evolve into commercial products.