Introduction: A Changing Landscape

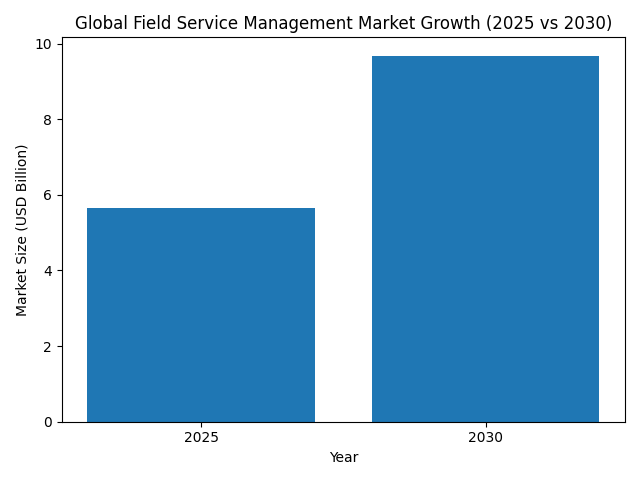

Field service management (FSM) enters 2026 at a pivotal moment. The market for FSM software and related solutions - tools that coordinate technicians, work orders, scheduling and customer interactions - is expanding rapidly, projected to grow from USD 5.64 billion in 2025 to USD 9.68 billion by 2030 msidata.com.

This growth rides a wave of technological innovation and heightened expectations: over 72% of service organizations report using artificial‑intelligence (AI) tools, and 93% of companies have at least partially implemented AI. At the same time, field service firms face a widening talent gap, with an estimated 2.6 million worker deficit across service sectorsmsidata.com. Customers demand faster, more transparent service, while regulators and stakeholders push for sustainability and stronger governance.

For owners and operations leaders in service companies - from HVAC contractors and utilities to telecom operators and manufacturers - 2026 is the year to transform field operations from reactive fixes to proactive, data‑driven service. This article synthesizes market research, expert analyses, and field practices to explore the technologies, workforce dynamics, customer experience trends, sustainability initiatives and sector‑specific developments shaping the future of FSM. It concludes with strategic recommendations to help leaders navigate these changes and seize opportunities.

Macro Trends and Market Outlook

Market Expansion and Investment in AI

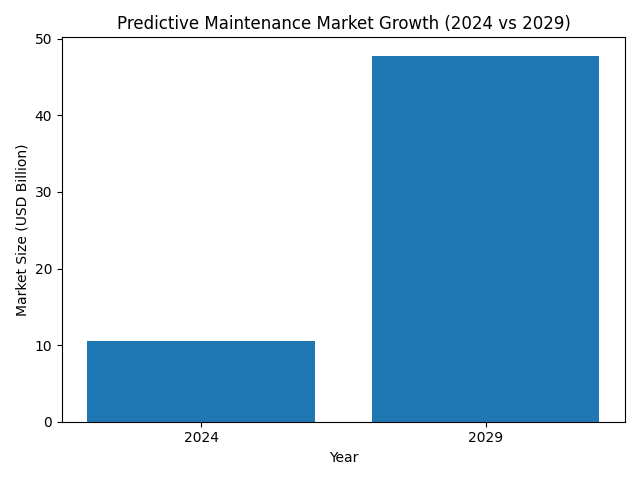

FSM is one of the fastest‑growing segments in enterprise software. Analysts project the market will increase at a compound annual growth rate (CAGR) of 12.5 %, rising from USD 5.64 billion in 2025 to USD 9.68 billion in 2030. Drivers include demand for predictive maintenance, mobile workforce enablement and data‑driven customer experiences. The predictive maintenance market—underpinning many FSM use cases - is expected to jump from USD 10.6 billion in 2024 to USD 47.8 billion by 2029, illustrating how IoT sensors and analytics are transforming service into a proactive discipline. In parallel, the self‑service solutions market (customer portals and automated scheduling) is forecast to expand from USD 12.9 billion in 2022 to USD 34.35 billion by 2027, highlighting consumer appetite for on‑demand interactions.

AI adoption underpins much of this growth. Surveys show that 93 % of service organizations have partially implemented AI, and 88% report improved equipment uptime and better customer experiences due to AIgeotab.com. Nearly 75 % of companies say AI improves first‑time fix These data points reveal that AI is not a future aspiration but an operational reality.

Chart 1: FSM Market Growth (2025–2030)

italic textFigure 1 – The global field service management market is projected to climb from USD 5.64 billion in 2025 to USD 9.68 billion by 2030*

Chart 2: Predictive Maintenance Market Growth (2024–2029)

Figure 2 – The predictive maintenance market is forecast to quadruple by 2029, climbing from USD 10.6 billion in 2024 to USD 47.8 billion

Technology Innovations Reshaping FSM

AI & Automation: From Assistance to Autonomy

AI is moving beyond basic scheduling and recommendations towards agentic decision‑making. Most field service platforms now embed AI to optimize technician schedules, route assignments and parts ordering. According to surveys, 75% of companies report that AI improves first‑time fix rates, and 62% expect AI to transform inventory management within a year. AI copilots assist dispatchers by analyzing job urgency, location, technician skill sets and traffic patterns to generate optimized schedules; in some cases, the AI autonomously assigns jobs and informs managers only when intervention is needed.

AI’s scope is also broadening to predictive analytics, where algorithms analyze sensor data and historical work orders to forecast equipment failure. For example, predictive models can detect anomalies in vibration or temperature data from an HVAC system and automatically schedule maintenance before the customer notices a problem AI also supports back‑office automation—auto‑generating estimates, invoices and service reports—freeing up dispatchers and technicians to focus on higher‑value tasks. Read more about AI in Field service management

IoT and Predictive Maintenance

IoT sensors are the backbone of predictive maintenance. Tiny devices attached to machines transmit real‑time data on vibration, temperature, pressure and usage, feeding analytics platforms that predict wear and schedule service. Organizations implementing predictive maintenance report dramatic reductions in unplanned downtime and maintenance costs. Analysts forecast that predictive maintenance will prevent 80% of equipment breakdowns by 2030. Industrial organizations deploying IoT sensors across factories, power grids and fleets have already observed unplanned downtime reductions of up to 30%.

In 2026, expect adoption of digital twins - virtual replicas of physical assets that simulate performance under different conditions- to accelerate. By combining real‑world sensor data with simulation models, field service teams can refine maintenance schedules, test new processes and proactively identify failure modes.

Mobile, AR/VR & Remote Assistance

Field operations are now mobile‑first. Technicians increasingly rely on smartphones and tablets to receive job details, update work orders, capture photos, collect signatures and process payments on site. Mobile apps integrate with back‑office systems, eliminating manual data entry and enabling real‑time communication between dispatchers and technicians. According to research, mobile tools save over 75% of workers’ time by streamlining scheduling and routing

Augmented reality (AR) and virtual reality (VR) are maturing beyond experimental pilots. Gartner predicts that nearly half of field service deployments will use AR tools by 2025. When wearing AR headsets or using smartphone apps, technicians can see digital overlays such as wiring diagrams or step‑by‑step instructions on top of real equipment. This enables remote experts to guide on‑site technicians in real time; one firm reported 37 % faster repairs and 28 % lower expert travel costs after implementing AR. VR simulations support training, allowing new hires to practice in risk‑free environments and reducing onboarding time by nearly 44%.

Data Integration, Analytics and Cybersecurity

FSM software is becoming a hub that unifies data from customer relationship management (CRM), enterprise resource planning (ERP), inventory and scheduling systems. Connected platforms support real‑time dashboards tracking metrics like first‑time fix rates, repeat visits, customer satisfaction and equipment health. As data volumes grow, advanced analytics and AI models extract insights that drive process improvement and revenue opportunities. Integration raises security stakes. Each sensor, mobile device and cloud integration expands the attack surface. Industry experts emphasize secure‑by‑design architectures and zero‑trust strategies that authenticate every device and user. Data governance features—such as automated audit trails for work orders and customer interactions—help service organizations meet compliance requirements.

Workforce Dynamics: Bridging Talent Gaps and Empowering Teams

Labor Shortage and Skills Evolution

Field service organizations face a structural talent shortage. An estimated 2.6 million worker deficit across service sectors exists, and 75 % of technicians report needing more technical expertise. Nearly half of technicians are over 50 years old, while younger generations show limited interest in field work. To meet demand, firms increasingly rely on contingent labor, with 77 % of organizations engaging freelancers or subcontractors.

Training, Upskilling and Knowledge Transfer

To address the skills gap, leaders invest in structured training programs and knowledge‑sharing initiatives. Companies are creating internal academies, partnering with trade schools and launching apprenticeship programs. AR/VR training tools allow novices to practice complex repairs in virtual environments, which accelerates learning and reduces risk. Knowledge transfer is critical: capturing veteran technicians’ expertise in digital knowledge bases and mentoring programs ensures that institutional wisdom is preserved.

Hybrid and Blended Workforce Models

Hybrid work isn’t just for office jobs; it also applies to field service. Blended models combine full‑time employees with part‑time or on‑demand gig workers, enabling organizations to scale up or down depending on demand. In North America, the mobile workforce—including field technicians, drivers and mobile sales reps—comprises approximately 93.5 million workers, or around 60 % of the workforce. With large geographic territories and seasonal spikes, flexible labor strategies help service organizations meet customer needs while controlling costs.

AI‑Assisted Scheduling and Self‑Service

AI‑powered scheduling tools analyze service demand, technician availability, skills and travel time to produce optimized rosters. Such systems automatically create schedules that reflect seasonal fluctuations and absentee patterns, allowing managers to reallocate resources more effectively. Many enterprises plan to increase AI investments, and forecasts suggest that 70 % of large companies will use AI‑based scheduling by 2025.

Employee self‑service features—where technicians can swap shifts, request time off or update their availability via mobile apps—are becoming standard. Over 65 % of organizations have implemented self‑service functions, and adoption boosts Gen Z retention by 34 %. Allowing workers to manage their schedules fosters flexibility and engagement while reducing administrative burden.

Employee Well‑Being and Retention

With fewer workers handling more jobs, burnout is a real risk. Surveys indicate that 66 % of technicians experience job burnout at least once a month. Leaders are responding by prioritizing work‑life balance, equitable shift assignments and wellness programs. AI scheduling tools help mitigate overbooking and minimize “windshield time,” while automation reduces administrative tasks, giving technicians more time for meaningful work. Organizations that invest in technician well‑being not only retain talent but also deliver better service experiences.

Workforce Statistics Table

| Metric | Statistic | Source |

|---|---|---|

| Worker deficit across service sectors | 2.6 million | |

| Technicians needing more technical expertise | 75 % | |

| Organizations using contingent labor | 77 % | |

| Size of the North American mobile workforce | 93.5 million workers (~60 % of workforce) | |

| Organizations with self‑service adoption | >65 % | |

| Retention boost from self‑service | +34 % (Gen Z retention) |

Customer Experience: From Reactive Fixes to Proactive Partnerships

On‑Demand Self‑Service and Omnichannel Engagement

Modern customers expect to manage service appointments like they manage online shopping—anytime, from any device. Service providers increasingly offer self‑service portals where clients can book appointments, view technician locations, receive quotes and pay invoices without calling a dispatcher. The self‑service solutions market is projected to grow from USD 12.9 billion in 2022 to USD 34.35 billion by 2027. Community forums and knowledge bases allow customers to troubleshoot simple issues themselves, reducing inbound calls and boosting satisfaction. Customer engagement also spans multiple channels: phone, email, SMS, web chat and mobile apps. Leading providers integrate these channels so customers can start a conversation in one medium and continue in another seamlessly.

Real‑Time Communication and Transparency

Customers no longer tolerate vague appointment windows. FSM software now delivers real‑time updates via SMS or mobile apps, showing technicians’ estimated time of arrival (ETA), name and photo. These notifications reduce no‑shows and provide peace of mind. Some companies enable customers to track technicians on a map and proactively communicate delays. Transparent communication extends to service outcomes; clients receive digital checklists and photos documenting completed work, enhancing trust and accountability.

First‑Time Fix and Outcome‑Based Service

While meeting service‑level agreements (SLAs) remains important, the industry is shifting toward outcome‑based metrics such as first‑time fix rate, equipment uptime and customer satisfaction. AI and predictive analytics play pivotal roles in achieving first‑time fixes: by analyzing equipment histories, IoT data and similar past jobs, dispatch systems can assign technicians with the right skills and ensure they bring the necessary parts. Companies adopting predictive maintenance significantly reduce emergency repairs and unplanned downtime. In manufacturing and industrial contexts, outcome‑based contracts guarantee performance and uptime instead of billing solely for time and materials.

Personalization and Human Touch

Despite automation, human relationships remain central. Customers appreciate technicians who remember past issues, communicate clearly and act as trusted advisors. Connected FSM platforms provide technicians with customer history, service preferences and context, enabling personalized interactions. AI complements this by suggesting relevant services or maintenance plans based on customer data. However, the objective is not to replace people; rather, AI automates mundane tasks so technicians can focus on empathetic, value‑added interactions. Companies that treat jobs as relationships rather than transactions cultivate loyalty and repeat business.

Proactive and Predictive Service

The ultimate customer experience is one where issues are resolved before they become problems. IoT sensors and analytics enable providers to detect anomalies and notify customers with suggested corrective actions. For example, a utility might notice voltage fluctuations on a smart grid and dispatch crews proactively, sending customers a message: “We detected an issue and have already dispatched a crew; service should continue uninterrupted.” In home services, seasonal maintenance reminders ensure furnaces are serviced before winter, preventing emergencies. Proactive outreach positions service companies as trusted partners and builds enduring loyalty.

Sustainability, Compliance and Governance

Sustainability is becoming a strategic imperative for field service firms. Routing optimization reduces travel distances and fuel consumption, lowering carbon emissions. Digital invoicing and documentation eliminate paper waste and improve traceability. Smart building technologies monitor energy use, enabling technicians to adjust settings for optimal efficiency. Many organizations track emissions from service activities; one survey found that 79 % of manufacturers now track emissions as part of their service operations.

Compliance and governance are also critical. FSM platforms increasingly include automated audit trails to record who performed what actions, when and where. This functionality helps organizations meet regulatory requirements and demonstrate accountability to customers and auditors. Secure data storage and privacy controls are paramount as sensitive customer and equipment data flows across cloud systems.

Sector Spotlights

While the overarching trends of AI, IoT, mobile enablement, customer experience and sustainability apply across industries, the way they manifest differs by sector. The following subsections provide concise snapshots of how major industries will experience field service in 2026.

Home Services (HVAC, Plumbing, Electrical, etc.)

Home service providers are adopting AI‑driven scheduling and route optimization to handle high volumes of short jobs across residential neighborhoods. Platforms like ServiceTitan integrate AI to match jobs with technician skills and generate optimal routes, reducing travel time and fuel costs. Self‑service portals allow homeowners to book appointments, approve estimates and track technician arrival, while some firms provide tiered pricing options (good/better/best) online. Talent shortages remain acute; contractors are launching apprenticeship programs and using AR‑based training to grow their own technicians. Seasonal demand surges (e.g., heatwaves or cold snaps) are mitigated using AI to forecast weather‑driven service needs and adjust staffing.

Utilities (Electric, Gas, Water)

Utilities prioritize reliability and safety. They are deploying IoT sensors across grids and pipelines to monitor voltage, pressure and temperature and send alerts before failures occur. Drone inspections and remote monitoring reduce the need for crews to access dangerous or remote sites. When field teams are needed, route optimization and dynamic dispatching ensure fast response times during outages. Utilities face a looming retirement wave among linemen and technicians, so they are investing in VR training programs to transfer knowledge while minimizing risk. Customer communication has improved dramatically: outage maps, text alerts and proactive updates keep customers informed, and reliability metrics are increasingly tied to regulatory compliance.

Telecommunications (Telecom Operators, Internet Service Providers)

Telecom companies manage massive installation and repair workloads. AI‑powered route optimization yields 20 % reductions in travel time and 15 % more jobs per day. Live GPS tracking and dynamic scheduling add 2–3 productive hours per technician each day. Telecom providers often combine full‑time crews with contracted specialists for fiber‑optic rollouts and 5G infrastructure upgrades, necessitating robust systems to manage mixed labor models. Predictive analytics help maintain network equipment, while AR tools enable remote experts to guide technicians working on towers or remote base stations.

Manufacturing (Industrial Equipment Service)

Manufacturers increasingly offer servitization—selling outcomes and uptime rather than only products. In surveys, 39 % of manufacturers cite servitization as central to growth. Many manufacturers invest in cloud, AI, IoT and AR technologies to modernize service operations. Predictive maintenance is critical; sensors on turbines, robots and other machinery send data to AI models that detect wear and schedule repairs before failures occur. Industrial companies also embrace digital twins and sustainability; 97 % cite sustainability as a strategic priority and 79 % track emissions from service activities. Training academies and AR/VR programs help build skills amid labor shortages.

Construction (Heavy Equipment Service and Field Operations)

Construction service companies support heavy equipment fleets (cranes, bulldozers, excavators) and infrastructure projects. IoT sensors and telematics monitor engine health, hydraulic pressure and usage hours, enabling predictive maintenance that minimizes downtime. AR guides mechanics through complex repairs, overlaying digital instructions on engines. Mobile apps replace paper checklists for daily inspections and safety logs, improving compliance and tracking. Route optimization is used to dispatch mechanics across dispersed job sites; one logistics team reduced fuel use by 22 % through live traffic‑aware routing. Talent shortages in heavy equipment mechanics are addressed through in‑house training programs and partnerships with vocational schools.

Strategic Recommendations for Owners and Operations Leaders

-

Adopt a Platform Approach: Choose FSM software that integrates scheduling, dispatch, inventory, CRM and analytics into a unified platform. Ensure it supports open APIs for connecting to existing enterprise systems.

-

Start with High‑Impact AI Use Cases: Focus initial AI investments on scheduling and route optimization, where immediate ROI is visible. Then expand into predictive maintenance and automated documentation. Begin with “human‑in‑the‑loop” systems and evolve toward partial autonomy as confidence grows.

-

Invest in Data Infrastructure: Implement IoT sensors on critical equipment and unify data streams from multiple sources. Build dashboards that track KPIs such as first‑time fix rate, job duration, customer satisfaction and technician utilization. Use these insights to iterate on processes and identify new revenue opportunities.

-

Close the Skills Gap: Develop training programs and knowledge‑transfer initiatives. Leverage AR/VR for immersive training and maintain digital knowledge bases accessible via mobile devices. Create career pathways and mentorship programs to retain experienced technicians.

-

Embrace Hybrid Workforce Models: Use a blended mix of full‑time employees, freelancers and subcontractors to balance capacity and flexibility. Deploy AI‑assisted scheduling and mobile self‑service tools so staff can manage their shifts and time off. Monitor contractor performance to maintain consistent service quality.

-

Prioritize Customer Experience: Offer self‑service portals, real‑time updates and personalized interactions. Empower technicians to act as advisors by providing them with customer history and context. Evaluate success using outcome‑based metrics like first‑time fix rate and net promoter score.

-

Commit to Sustainability and Compliance: Optimize routes, digitize paperwork and track emissions. Select FSM platforms with built‑in audit trails and security features to meet regulatory requirements. Communicate sustainability efforts to customers and stakeholders.

-

Cultivate a Change‑Ready Culture: Encourage experimentation and continuous learning. Involve technicians and managers in selecting new tools and processes. Celebrate quick wins and learn from failures to maintain momentum. The pace of innovation will continue to accelerate; an adaptable mindset is the greatest asset.

Conclusion

Field service management in 2026 is defined by technological sophistication, human empowerment and customer centricity. AI and analytics are no longer optional; they are embedded into every aspect of scheduling, dispatch, maintenance and customer engagement. IoT and predictive maintenance transform service from reactive repair to proactive partnership. Meanwhile, workforce challenges—aging talent, skill gaps and worker scarcity—demand creative solutions, from AR‑based training to hybrid labor models and employee self‑service tools. Customers expect on‑demand scheduling, real‑time updates and personalized interactions; meeting these expectations requires both digital investments and a human touch. Sustainability and compliance round out the agenda, ensuring that service operations are environmentally responsible and secure.

The opportunities are vast. By embracing integrated platforms, targeted AI use cases, rigorous data practices, continuous training, flexible workforce models and customer‑centric processes, service organizations can turn 2026 into a breakthrough year. Leaders who act now—aligning technology with people and processes—will not only survive but thrive, delivering field service experiences that are smarter, faster and more sustainable than ever before.